Buy Online

- Package Deals

- Extreme Security Chain and Lock Deals

- High Security Chain and Lock Deals

- Medium Security Chain and Lock Deals

- Security Chain and Multiple Lock Deals

- Shed Shackle, Protector Chain and Lock Deals

- Door Security Package Deals

- Ground Anchors

- Chains (without padlocks)

- Shed Shackle

- Padlocks

- Anti-Pinch Pin

- Door Security

- Extras and Upgrades

- Fitting Kits

- Hardware, Fixings, Drills

- Chain Offcuts & Sleeves

- Alvecote Wood Related

Your Cart

Information

Sub Major Bury-in-Concrete Ground Anchor

- Features

- Angle Grinder Resistance

- Straightforward to install?

- Attention to Detail

- Chain Capacity

- Dimensions & technical details

- Compatible with Block Paving and other Paved Areas

- Certifications

New! The Sub Major is an extreme security bury-in-concrete ground anchor intended to provide an exceptional level of security for the most demanding situations.

It has Sold Secure Ground Anchors Diamond approval - it is the first ground anchor ever to achieve this level of approval. Note that this involves significantly more angle grinder resistance than Motorcycle Diamond approval, which it also has! The Sub Major is also Police approved (under the Secured-by-Design scheme).

And it is made in Britain! This page gives more technical information about the Sub Major ground anchor.

Sub Major Anchor Features

The Sub Major Ground Anchor offers the following features:

- It is an extreme security ground anchor to be installed in fresh concrete

- The main structure is fabricated out of 4mm and 6mm thick laser-cut steel plates

- The bridge is deliberately made out of the thicker, 6mm, steel to give even more protection from attacks

- It is fully seam welded

- It is Sold Secure Ground Anchors Diamond approved. That is a new standard, higher than Motorcycle Gold and also higher than Motorcycle Diamond. This means it has been tested to confirm extreme angle grinder resistance and is approved for use with motorcycles, vehicles, caravans, Quads/ATVs, bicycles, etc.

- It is Police Preferred Specification - important to house builders, this ground anchor has genuine Police approval and is suitable for credit points under the Safer Homes initiative.

- It is large enough to take the largest known high quality large-link security chains that cannot be bolt-cropped, including the extreme security Protector 22mm Titan chain. Many ground anchors cannot cope with these chains.

- Angle grinder attacks are virtually impossible!

- Bolt-cropping is impossible!

- It requires a hole to be dug and filled with fresh concrete as part of the installation process. That is not as easy as the fitting process for our other anchors, but the Sub Major gives a higher level of protection than any of them.

- It has two-stage corrosion protection with a zinc phosphate electrophoretic pretreatment and tough powder coating finish.

- It is Made in Britain - Support British industry!

Angle Grinder Resistance

We designed the Sub Major for the maximum practical resistance to angle grinder attacks.

The Sold Secure Ground Anchors Diamond test report says:

"The product was cut along the bridge component, in an attempt to remove the central section and release the chain; the angle grinder successfully cut the initial part of the bridge, but upon plunging into the deepest part, the load on the wheel was too great, the angle grinder overloaded and cut out. Repeated attempts were made to cut through in the time allowed, however the same issue occurred and the angle grinder continued to cut out each time it was plunged into the deepest part of the central bridge."

"Note: This attack was performed on the bench, not submerged in concrete. It would be of considerably greater difficulty to achieve even this level of progress with a layer of concrete adding further hindrance to the angle grinder.!"

We also provide guidance on achieving an even higher level of deterrent against angle grinders (see below).

Straightforward to Fit

All of our ground anchors are designed with the person that will install it kept in mind. This is our only ground anchor that needs a hole to be dug/prepared and fresh concrete to be laid. The instructions are written in a detailed, step-by-step way to guide you through the process of achieving an extreme-security fitting, even if you are not that familiar with laying fresh concrete. We are happy to give advice by e-mail.

Attention to Detail

We made our reputation by giving more attention to detail than most competing products. The Sub Major is no exception!

The Sub Major is fabricated out of precision laser-cut steel plates, folded and then welded together. This allows us to achieve an extreme level of security without needing a huge hole to be dug or a massive load of concrete to be laid. The size of the hole in the ground is reduced because we have folded the outer edges of the anchor to be vertical. The openings are square and plenty large enough to accept the largest known chains.

Our design allows us to deliberately use thicker steel for the bridge section. Concrete-in ground anchors are very unlikely to be attacked by thieves but, even so, we wanted to achieve an extreme level of protection with this product so we made the bridge piece thicker than the rest of the product. As well as thicker steel, the bridge is also deliberately deep, meaning that there is a significant amount of concrete filling the space and thus providing further protection to the metalwork. If you wish, our fitting instructions also give guidance on incorporating an additional steel bar through this bridge section, making it even harder for a thief to chisel away the concrete that is protecting the steel. We try to think of likely attack vectors and try to stop them!

The Sub Major also has an enlarged footplate to improve retention in the concrete and also to make the installation process easier.

In addition to this, the Sub Major is protected with an electrophoretic coating plus powder coating and we provide plastic plugs to cover the holes when the anchor is not in use.

The large footplate provides support for the whole anchor before you even mix any concrete! Having the anchor at the right level and properly upright, in advance, means that the concreting process can be much more straightforward and is less likely to require adjustment as you near the final surface level - The ground anchor should be already in the right place so there should be no surprises or big adjustments required!

The plastic plugs are a simple push fit after the anchor is installed. They can be readily removed with a blunt knife, pallet knife or screwdriver. Bury-in ground anchors can present an ankle-twisting hazard when they have holes in the ground when they are not being used. The plastic plugs guard against this risk. Plus, they help to keep leaves and other muck out of the holes! The Sub Major ground anchor incorporates a drainage tube so rain getting into the openings can drain away, but these plastic plugs will help to keep the inside of the anchor relatively clear.

Chain Capacity

The Sub Major ground anchor can cope with the following combinations of Protector chains:

| Example Chain Combinations | Comments |

|---|---|

| Protector 22mm | Easy |

| Protector 22mm plus Protector 19mm | OK |

| 2 x Protector 19mm | Easy |

| 2 x Protector 19mm plus Protector 16mm | OK |

| More chain combinations | TBC |

Dimensions, Design and Technical Details

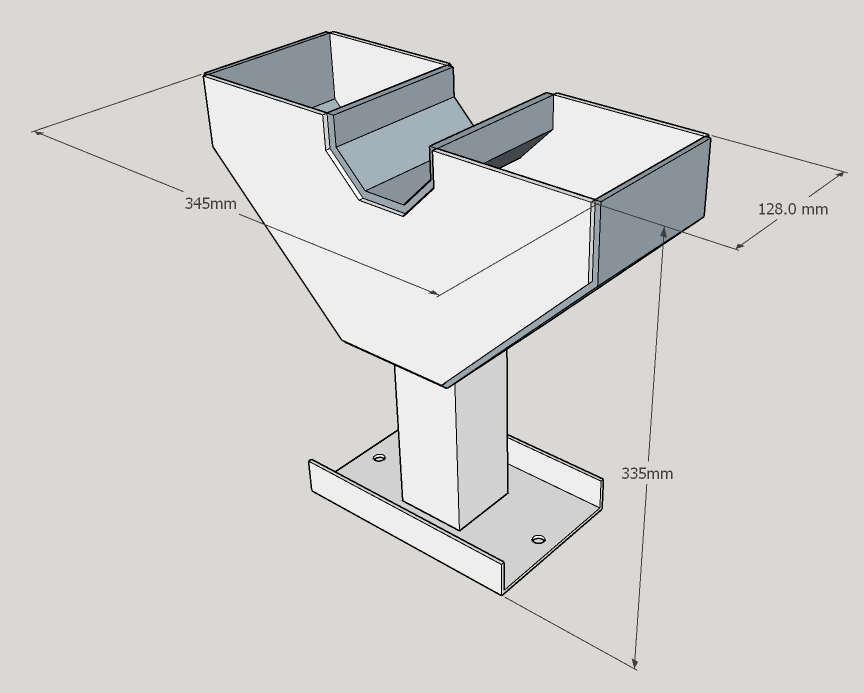

- Overall Dimensions: 345mm x 130mm x 335mm high (dimensions are subject to manufacturing tolerances)

- Square Openings: Approximately 120mm square, internal

- Typical hole size required: 450mm x 300mm x 450mm deep

- Typical amount of ready-mix concrete required: Approximately 6 x 20kg bags plus a similar amount of ballast or hardcore

- Steel Thickness: 6mm for the bridge and 4mm for the rest of the main structure. The footplate is folded out of 3mm thick steel and seam welded to the drainage tube

- Finish: Electrophoretic zinc phosphate followed by powder coating: Black.

Block Paving and Paving Slabs

This ground anchor is suitable to use in an area covered with paving slabs or block paving. One or several slabs/blocks will need to be removed in order for the hole to be dug. The concrete can be finished to end up level with the surrounding area to give a neat result.

Please note that no ground anchor is suitable for fixing directly to the block paving itself! Ditto paving slabs! These can all be lifted away as they are not retained by anything, so any anchor that was fitted to blocks or slabs themselves will give negligible security. The Sub Major can be fitted in these situations but only by removing some blocks/slabs and digging down into the ground below.

High quality - Independent Certification

The Sub Major has Sold Secure and Police approvals.

Our approval certificates are available online.